Cameleon Web Design Agency - The Best Web Design CompanyGenerative AI in Manufacturing Industry

Generative AI in Manufacturing Industry

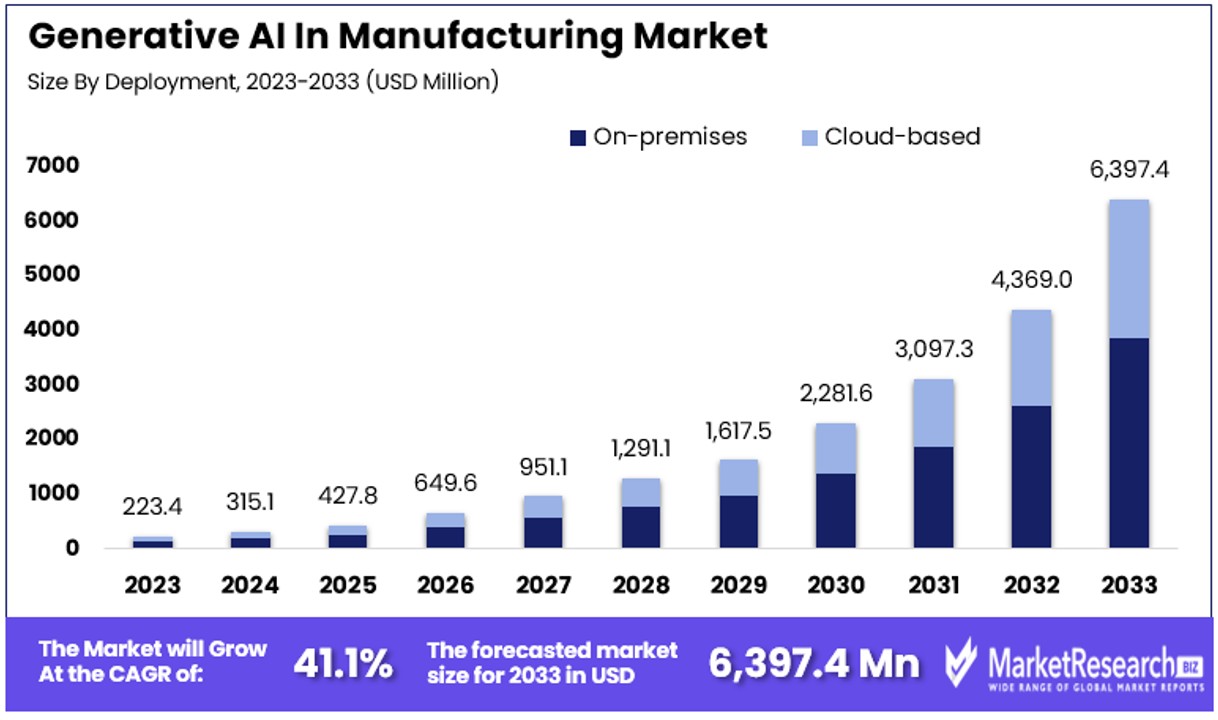

Generative artificial intelligence is set to revolutionize the manufacturing industry with a projected market value of USD 6 billion by 2032, growing at a remarkable compound annual growth rate of 41.06% from 2023 to 2032 [1] Market Research.

Cameleon Media presents 10 practical use cases of generative AI in the manufacturing sector, its benefits, challenges, and solutions to address them:

- Lead and revenue generation

- Customer-centric content creation

- Search engine optimization (SEO)

- Customer support automation

- Product and content discovery

- Technical document research and synthesis

- Contextual data understanding

- Product design and development

- Supply chain management

- Production and inventory management

10 Practical Generative AI Use Cases

The manufacturer operates under never-ending pressure to enhance production processes, optimize supply chains, deliver high-quality products to customers, and quickly adapt to dynamic market trends. To overcome these challenges, the adoption of generative AI becomes incredibly compelling and promotes highly efficient, connected, and smart manufacturing operations.

To cleverly integrate the capabilities of Generative AI in manufacturing, an understanding of its real-world usage in respective operations is crucial. In this section, we have explained the gen AI use cases in manufacturing.

1. Lead and revenue generation

Strategic generative AI tools can help with lead generation – lead capture, qualification, and scoring. You can easily rank and prioritize leads based on several factors, like demographics, online behavior, and purchase patterns with AI. Doing so enables you to classify them on a spectrum as interested or ready to buy.

Here’s how you can accomplish this:

- Offer valuable resources in exchange for customer information, like whitepapers, ebooks, or research papers.

- Use chatbots and conversational AI tools to engage website visitors and capture leads.

- Leverage predictive analytics to analyze historical data and identify prospects most likely to convert into paying customers.

- Create targeted advertising campaigns by focusing on the right audience segments, interests, and keywords.

- Nurture leads throughout the customer journey with personalized campaigns and messages.

For instance, you can use AI to determine the ideal keywords and bid range for your paid search campaigns and predict the performance of future PPC campaigns.

2. Customer-centric content creation

Industrial content creation is challenging since creating factually accurate and engaging content often requires input from busy subject matter experts. Industrial buyers conduct extensive online research before making purchasing decisions. Thus creating consistent, informative, and technically accurate content is essential for manufacturing companies.

Buyer persona creation : You must be familiar with the concept of buyer personas? Fictional representations of your ideal customers giving you insights about their pain points, goals, challenges, motivations, behavior, and interests. Generative AI can help you create detailled customer personas that showcases their pain points at each stage of the buying process.

- Collect and analyze customer data.

- Develop realistic customer profiles.

- Create personas based on specific use cases.

- Chat with buyer personas.

Valuable content creation : Leverage your AI-generated customer personas to generate both short-form and long-form valuable content at scale. Leverage that answers customers questions and offers solutions to their pain points. This saves a lot of time and gives you the creative liberties to work with.AI-generated text can be used to:

- Create new content like blog posts, emails, and social media posts.

- Design ad copies and product descriptions.

- Write scripts for video ads and product demos.

Image and video generation : Tools like DALL-E, Runway, and Midjourney can generate images and videos from textual prompts. They make use of generative adversarial networks (GANs) that help them with text-to-image translation. This ability can help marketers do the following things:

- Generate high-quality images, video ads, and product demos.

- Create logos and other creative brand assets.

- Develop images for social media posts.

You can insert AI voiceovers and music to create engaging ad videos, which can help increase brand awareness and conversions. One prime example of a brand using generative AI in advertising is Heinz, which created the Heinz A.I. Ketchup, a short video ad to demonstrate the prominence of its signature bottle design.

3. Search engine optimization (SEO)

Successful SEO project requieres a thorough keyword research. Experts need to analyze tons of keywords, their competitors, and user intent to build an SEO campaign that works. AI makes this process easier by sorting out keyword data and listing high-performing keywords. Furthermore, you can:

- Discover topic clusters related to your industry.

- Conduct keyword research by search intent.

- Identify keyword gaps and opportunities.

- Develop content in line with SEO parameters.

All in all, a content marketer can learn about the topics, subjects, and words their audience searches for online and cater to the same with relevant content.

4. Customer Services and Support

Redefining customer services through the intersection of large language models, generative AI and manufacturing will soon become the new norm. GenAI-powered chatbots and virtual assistants enable quicker interactions with customers based on their unique needs, ensuring immediate resolution of issues, analyzing customer queries, and providing accurate, step-by-step guidance for troubleshooting.

The advancement of LLM allows GenAI to engage with customers in more natural and have human-like conversations. The solution can operate around the clock, responding to reviews and contributing to common customer queries related to orders, exchanges, returns, billing, etc. Additionally, this transformative technology can serve as the representative of the manufacturer to enhance client experience and efficiently manage field inquiries.

5. Product and content discovery

Using gen AI, manufacturers gain an efficient method to match requirements to the specifications of products they buy, and provide the same service to their customers. Gen AI-enabled sales applications can provide sales recommendations based on historical sales data, in-stock data, master data, and more.

The sales recommendations can be generated using special machine learning algorithms equipped with continuous or real-time feedback functions to optimize the suggested results. Results could be combined with more descriptive statistics on sales data joined with meta-information that is uploaded by sales agents, giving a clear visibility into the buying process.

6. Document search and synthesis

In manufacturing, product and service manuals can be notoriously complex — making it hard for service technicians to find the key piece of information they need to fix a broken part. Ordering and quoting can be very complex, too, with sales teams often having to decipher a huge array of information before creating a customer quote.

Gen AI can quickly sift through generations of documents throughout the product lifecycle, extracting and summarizing the information needed by sales teams and technicians. For example, it can present servicing instructions in an easily digestible, step-by-step format so technicians can get straight to work. And it can synthesize purchase orders and quickly provide customers a quote, eliminating the need for sales teams to manually cross-reference emails with inventory availability.

7. Contextual data understanding

Data systems often cause major problems in manufacturing firms. They are often disparate, siloed, and multi-modal. Various initiatives to create a knowledge graph of these systems have been only partially successful due to the depth of legacy knowledge, incomplete documentation and technical debt incurred over decades.

IBM developed an AI-powered Knowledge Discovery system that use generative AI to unlock new insights and accelerate data-driven decisions with contextualized industrial data. IBM also developed an accelerator for context-aware feature engineering in the industrial domain. This enables real-time visibility into process states (normal/abnormal), alleviates frequent process obstructions, and detects and predicts golden batch.

IBM built a workforce advisor that uses summarization and contextual data understanding with intent detection and multi-modal interaction. Operators and plant engineers can use this to quickly zero in on a problem area. Users can ask questions by speech, text, and pointing, and the gen AI advisor will process it and provide a response, while having awareness of the context. This reduces the cognitive burden on the users by helping them do a root cause analysis faster, thus reducing their time and effort.

8. Product Design and Development

The manufacturing operation revolves around products, right from designing, manufacturing, and catering. In the core process of developing new products or constantly refining existing ones, generative AI incorporation significantly impacts product engineering through its newfound speed and agility.

Generative AI in manufacturing industry allows product engineers to bypass time-consuming research and focus directly on design by setting critical metrics within the model. GenAI leverages complex algorithms, to provide multiple conceptual design options, automate design optimization, enable precise testing, and helps in achieving future-ready optimal product solutions.

It can generate realistic 3D models and digital twins of products and simulate product performance in design or virtual format, which empowers engineers to closely track, evaluate, and improve designs before manufacturing begins. Thus, generative AI is a comprehensive solution for designing and building robust and custom products by reducing the development cost and accelerating time to market for new products.

9. Supply Chain Management

GenAI’s ability to analyze data and generate content in multiple formats, including text, images, and videos, is revolutionizing supply chain management. Supply chain disruptions encompass significant challenges in manufacturing.

GenAI provides manufacturers with a great extent of visibility across interconnected parts. It also adds value by recommending and selecting suppliers through analysis of various factors, including raw material availability, pricing, potential risks, etc. Additionally, insights from historical interactions with suppliers contribute to strengthening the relationship. it offers real-time insights into ongoing supply chain performance to ensure smooth transactions and improve the decision-making approach.

10. Production and Inventory Management

Inaccuracies in inventory management and suboptimal resource allocation are the primary reasons of cost overruns in the manufacturing industry. Poor demand forecasting, lack of inventory visibility, and overstocking and out-of-stock situations are key challenges that make the entire process inefficient. Generative AI for manufacturing industry can open the door to smooth and effective production and inventory management.

The GenAI model has the capability to analyze historical sales data, market trends, and other key factors. Based on these insights, it allows manufacturers to instill confidence in their production processes by optimizing them to match the dynamic requirements of stock. GenAI’s role in production planning helps in achieving optimal production schedules, ideal resource allocation, and workflow optimization.

Key Benefits of Leveraging Generative AI in Manufacturing Industry

Generative AI in manufacturing industry is a powerful force enabling fully automated factories and streamlining operations. Its potential for better integration allows it to identify inefficiencies and offer valuable insights across all aspects, from production to the supply chain and client interactions. This technology represents the future of smart manufacturing or industry 4.0 by maintaining high productivity and efficiency levels across operations.

In this section, we will explore the key benefits of generative AI in manufacturing in more depth.

Enhanced Productivity & Efficiency

GenAI in manufacturing processes helps automate repetitive tasks such as inventory management, supply chain operations, order processing, quality inspection, and engaging in human-like conversations with clients/customers. By automatically handling labor-intensive tasks, Gen AI allows manufacturers to utilize their resources for strategic and value-adding activities. Tasks that are powered by generative AI automation are known to be completed in no time, with more consistency and error-free, ushering improved productivity. Moreover, better control and visibility of operations, along with workflow optimization, makes it easy to achieve a higher degree of efficiency.

Smart Saving

Implementing generative AI in manufacturing industry as a cost-reduction strategy is the ideal approach to unlock its potential. Yes, integrating gen AI into operations can drive benefits in terms of operation optimization and cost savings. Manufacturing leaders can leverage this technology’s capabilities to identify bottlenecks and make optimal use of resources before implementing fundamental changes. Combining GenAI technology with digital twins permits engineers to save time and costs by conducting trial-and-error approach.

Costly disruptions occurring due to frequent downtimes can be avoided through Gen AI’s analytical skills. It helps track and address malfunctions in machinery before they escalate, thus reducing costs. Accurate forecasting of fluctuating demand and market trends allows the manufacturing industry to maintain inventory levels accordingly to avoid wastage. Overall, Gen AI offers a tremendously sustainable and profitable manufacturing environment to lead in future competition.

Data-Driven Decision Making

One of the top benefits of generative AI in manufacturing is its ability to enable smarter, data-driven decisions. The combination of Gen AI and data analytics offers benefits beyond traditional data analytics by empowering management hierarchy to uncover hidden patterns and complex relationships within the dataset. Access to accurate real-time insights helps making strategic decisions in various areas of the manufacturing, such as inventory management, supply chain management, quality assurance, production planning, and scheduling.

Improved Product Quality

Generative AI can be trained on vast amounts of product quality and visual inspection data, allowing manufactures to analyze and identify defects in real-time. This capability ensures an immediate jump in the rectifying process, significantly reducing waste.

Its ability to analyze massive datasets empowers on-floor labor to analyze production data and create predictive models of product quality. It enables proactive adjustments to maintain consistency and prevent defects. Furthermore, AI can optimize manufacturing parameters through simulations, identifying ideal settings for high-quality production, thus reducing variability and enhancing product consistency.

Addressing Manufacturing Industry Challenges with the Adoption of Generative AI

All entities associated with manufacturing structures are still struggling with some unremitting challenges. In this section, we will discuss the challenges faced by the manufacturing industry in the implementation of tech-enabled solutions and how generative AI helps to overcome those challenges effortlessly.

Data Management

- Challenge: The manufacturing industry generates a massive amount of data on a daily basis through ongoing execution of operations. Organizing and extracting actionable insights from this untidy data remains one of the critical challenges. It brings complexities and forces engineers to struggle with issues such as data quality and missing values.

- Solution: By leveraging generative AI models like variational autoencoders (VAEs) and generative adversarial networks (GANs), product and process analysts can promptly handle missing values and take actions to rectify noisy or erroneous data in their datasets.

Workforces Skills

- Challenge: Continuous upgrading of technology adoption in manufacturing workflows creates a gap between its execution and the knowledge & skills of the workforce required to implement it proficiently.

- Solution: Generative AI models aid in creating synthetic training data to upskill the manufacturing workforce and generate interactive learning materials like virtual simulations. Also, they automate report generation, providing data-driven insights and recommendations, easing the workload on data analysts, and empowering frontline workers with informed decision-making capabilities.

Data Privacy and Intellectual Property Protection

- Challenge: Safeguarding sensitive data and protecting intellectual property amid increasing AI integration.

- Solution: Generative models can be implemented to create synthetic, anonymized datasets and novel designs, prototypes, and product ideas, reducing the need to share sensitive information and mitigating the risk of theft or unauthorized use.

How to Implement Generative AI in Manufacturing Workflow?

Leveraging the power of generative AI in business operations can seamlessly unlock significant benefits in the forms of productivity, efficiency, and cost savings, but only if it is integrated effectively. For effective incorporation of GenAI within manufacturing workflows, organizations should be more careful and follow a systematic structure.

Here, we have mentioned a step-by-step process for the successful implementation of generative AI for manufacturing:

- Evaluate existing processes and workflow, focus on pain points by conducting a thorough analysis to identify inefficiencies, bottlenecks, and quality issues, and understand how GenAI can proficiently integrate to address them.

- Pre-determine specific use cases by prioritizing manufacturing workflows and tasks that can benefit most from GenAI integration, and clearly outlining the objectives, end result, and key performance indicators (KPIs).

- This step involves gathering and preparing data by identifying relevant data sources, such as production data, sensor readings, and maintenance logs, and ensure data quality, cleanliness, and standardization.

- Select and develop GenAI models by evaluating and choosing the appropriate algorithms and architectures that best fit the identified use cases and collaborate with data scientists and domain experts to train and fine-tune the models.

- Integrate GenAI into manufacturing workflows by seamlessly embedding the trained models into relevant processes, and developing the necessary infrastructure, APIs, and user interfaces.

- Monitor and continuously improve by establishing robust feedback mechanisms to track performance, analyze outcomes, and iterate on the models and integration strategies to maximize benefits.

- Foster a culture of adoption and collaboration by engaging cross-functional teams, promoting understanding and adoption of GenAI, and encouraging collaboration between domain experts and data scientists for continuous innovation.

Why Partner with Cameleon Media for Custom Generative AI Solutions in Manufacturing?

As a leading AI/ML service provider, Cameleon Media offers solutions built for continual improvement, ensuring that your manufacturing processes evolve alongside technological advancements. We understand the industry challenges and opportunities, which allows us to develop an AI-powered solution that directly addresses your unique business needs.

Our gen AI services are designed to accelerate digital transformation by optimizing a wide range of industry processes to improve productivity and reduce operational costs, providing your business with a competitive edge in the market. Our expert team of Gen AI specialists offers comprehensive support and collaboration, ensuring seamless integration and optimal utilization of AI technology in your business processes. Partner with Cameleon Media today and transform your business operation for the future.

Frequently Asked Question

Q: What is the future of GenAI in manufacturing?

A: GenAI’s future impact on manufacturing is enormous. It can smoothen out end-to-end production flows, foresee equipment failures before time, monitor quality by detecting anomalies and supply custom experiences for buyers. With the evolution of GenAI, it will be increasingly integrated into different parts of manufacturing which will have effects like efficiency driving productivity and innovation

Q: What is an example of generative AI in manufacturing industry?

A: One example of generative AI in the manufacturing sector involves using generative models to generate fake data for training machine learning algorithms. For example, VAEs or GANs can produce realistic images resembling defective products that enable the machine learning model to understand how to identify and categorize defects without needing a big dataset of actual-world malfunctioning goods. Such approach can significantly reduce costs and time needed for data collection as well as labeling processes.